Fans turn on often and work for a long time, and are almost never serviced. This is not from lack of time or negligence of the owner, but from the fact that this mechanism has become so firmly entrenched in everyday life that it is no longer noticed, and few people think about how and what to lubricate the floor fan with. But, like all mechanisms, a fan can break at the most inopportune moment. This can only be prevented by timely care.

Floor fan

The vast majority of floor models are designed in the same way: the impeller blades rotate with an asynchronous motor with a gearbox. All moving friction parts are in the engine, and it is in it that the grease must be poured. Lubricate engine parts at least once a year.

How to understand that it’s time to grease the floor fan?

Very simple:

- When you press the start button, the screw of an unlubricated device may simply not move.

- The propeller only moves by hand.

- The screw picks up speed very slowly.

All this indicates that the oil has completely left the rotation units and the friction force does not allow the motor to work normally.

Lubricating rotating parts of an induction motor

Before lubrication, remove all attachments and get to the engine. The engine must be disconnected from the mains. Removing the protective cover and disassembling the plastic case, the engine will open. Before lubrication, the engine is cleaned of contamination.

The order of the work:

- After removing the plastic casing and protective mesh, access to the motor is opened. The motor is disconnected from the rotary mechanism and wires.

- In the process, various debris and dust are wound around the shaft. It must be cleaned of contamination, while it does not need to be disassembled. It will be enough 2-3 times to popshikat

Household floor fan

- WD-40 onto the shaft base (where the bearing is) and twist the shaft with your fingers a little. The mixture will penetrate deeper into the bearing and wash all the dirt.

- After cleaning the shaft, it is necessary to wipe and drip a couple of drops of liquid machine oil for the sewing machines onto the bearing. I-20 oil is well suited for lubrication.

- The swivel mechanism is also cleaned of dirt. A thick grease of the type of solid oil is applied to the gears, and oil is dripped onto the bushes.

- After all operations, it is necessary to leave the motor parts until all the excess flows from them. At the end, the parts are wiped dry and the fan is assembled in the reverse order.

Some lubricants can corrode plastic, this will cause the device to break and have to be repaired or discarded. Before applying, read the instructions

Asynchronous motor bearing lubrication

Grease non-separable fan

Fixed fans most often can be found inside the system unit of a computer or laptop case. They are mounted on video cards and coolers, on which thermal grease is applied. It is called inseparable because the stator and primary windings are tightly sealed in a plastic casing, which is screwed to the cooling radiator. Ungreased and dusty motors begin to make a lot of noise and annoy the computer owner.

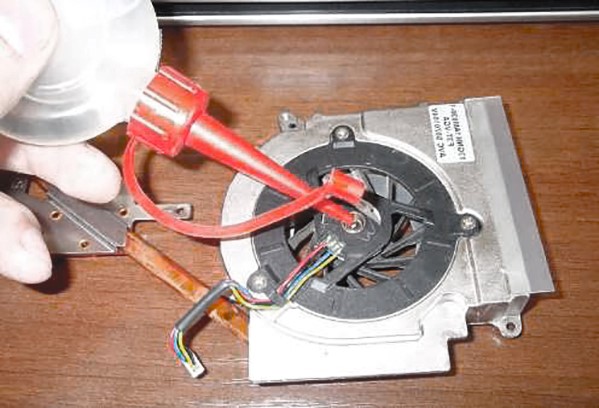

To lubricate a non-separable motor, access to the bearing must be obtained.In some models it is covered with a sticker, while in others it is tightly sealed with plastic.

How to lubricate a non-separable fan with a sticker

- Put a little machine oil into the syringe with a thin needle.

- Carefully peel off the sticker that covers the bearing.

- Place 5-6 drops of oil in the opened bearing. If the bearing is protected by a rubber gland, then it is not necessary to remove it - you can pierce it with a needle and inject oil.

How to lubricate a non-separable fan sealed with plastic

- Take a small drill with a centering tip (2-3 mm)

- Carefully make a hole on the bearing side, it is better not to use the power tool and drill it manually.

- Pour a few drops of oil with a syringe.

- Replace sticker or cover with cold welding.

Non-separable motor bearing lubrication

When drilling, small plastic chips can get into the bearing. If you feel that the shaft is sticking a little, you will have to wash the WD-40 bearing and only then drip the grease inside.

Exhaust Fan Lubrication

Exhaust motors due to lack of lubrication not only fail. They have powerful engines and large impellers installed, so a faulty exhaust motor starts to make loud unpleasant sounds. Plus, the engine starts to overheat and wedge.

Lubrication of the ventilation exhaust fan

- The exhaust motor is removed from the protective grill.

- The impeller is removed from the engine. The impeller fastening screw can become very dry to the thread because all the oil has dried. It can not be unscrewed sharply, you need to increase the effort gradually.

- 2-3 drops of engine oil are dripped onto the bearings. Pouring a lot of oil is not necessary, it will only hurt.

- After applying the oil, the shaft must be twisted so that it penetrates better to the metal balls.

- The fume hood is assembled in the reverse order and can be switched on immediately.

Exhaust fan disassembled

Lubricating the kitchen exhaust fan

Not all greases are suitable for lubricating a cooker hood motor. Shrus whether engine oil may not give any results. An improper composition corrects the situation only for a few days, then the engine again starts to overheat and make noise. In this case, a liquid silicone mixture can help to work in especially difficult conditions (temperature range from -40 to +300 degrees Celsius). Silicone will protect engine parts from grease, which is absorbed along with air. Otherwise, the lubrication process of the exhaust motor is the same as that of the ventilation motor. Disassemble the hood longer than the ventilation grill, but lubricate it more often.

If the grease does not help

Sometimes lubrication may not work, the impeller will still spin with difficulty. This means that the balls in the bearings have exhausted their life and begin to wedge. Only replacement of bearings with new ones will help here. This rarely happens, these are either very old models, or these are devices that were stored without preliminary conservation and became unusable from corrosion.

Exhaust fan in the ventilation system