A broken fan should not be thrown away immediately, it will be most reasonable to figure out the reasons and, if possible, repair the device. Often, fan malfunctions are not related to breakdowns, but simply require banal cleaning and lubrication.

Some types of mechanical damage can be repaired independently by replacing a failed part. It is more difficult to repair floor or table models with a more complex design. Since fans are included in most modern refrigeration and air conditioning devices, each case is individual. We will consider only the most common causes of breakdowns and how to eliminate them.

Damage to domestic floor fans

A repair approach for floor or desk fans should be rational. The presence of blocks for adjusting the speed, angle, and rotation of the fan greatly complicates the design. The main task is to identify the cause. If the problem is simple, then you can try to repair yourself.

The fan is noisy, but the blades do not rotate

The most common failure of floor fans is when the device makes a noise, but the blades remain motionless.

The reasons may be as follows.

- Dried or thickened bearing grease. It’s easy to identify the cause. The engine is disassembled and the presence and condition of the lubricant is checked.

- Mounted bearings on the shaft. This is due to the development of the resource of the bushings, which are made of bronze or brass.

- Motor malfunction. To check, it is necessary to disassemble the motor and check the resistance on the windings of the housing and the armature.

- Loss of capacitance due to failure of the capacitor. It is necessary to check the capacitance of the capacitor with a tester.

If the cause is lubrication, remove the remaining thickened lubricant by cleaning the parts with gasoline and add fresh engine oil to the bushings. Care should be taken to ensure that oil does not get on the motor windings.

Fan motor

In the case of bushings, you must look for new ones in the store or take them from another inoperative device. Restore worn out will not work.

In case of violation of the motor winding, you will have to rewind in the workshop or buy a new motor. It is difficult to independently restore the winding.

In the event of a malfunction of the capacitor, you must replace it with a new one from the store. If this is not possible, then it is easier to purchase a new fan.

The fan makes whistling sounds.

Whistling sounds may appear a few months after purchase. Fan buzzing or creaks due to deformation of the propeller or loosening of the bearings of the plain bearing. Exposure to the blades of direct sunlight or high temperature leads to bending and imbalance at the time of rotation. Indentation as a result of mechanical damage to the protective grill also leads to similar sounds, the tips of the blades begin to reach the surface of which.

Bearing failure

If extraneous noise appears, do the following:

- disconnect the device from the power supply;

- remove the protective grill, inspect it for deformations;

- remove the propeller, inspect the blades for possible bends;

- inspect the bearing hardware, check that the bolts are tightened.

The bending of the protective grill can be easily corrected by carefully straightening it with your hands to the desired state.

Note! In case of violation of the geometry of the blades, the propeller will most likely have to be replaced, since it is impossible to give the polyurethane the original shape at home.

If the cause of extraneous sounds was loosening of fasteners, then you just need to tighten all the bolts until the backlash is eliminated.

The device does not turn on

The absence of a fan reaction to pressing the power button can indicate a broken wire in the cable, a damaged cable connection to the terminals in the outlet, or a malfunction in the outlet itself. The keypad or the gearshift buttons themselves may also be damaged.

First of all, you need to check whether the control lamp lights up when you try to turn on the device.

If the light is off, do the following:

- measure the voltage in the outlet by connecting a workable device to it;

- unscrew the plug and check for damage at the places where the wires are connected to the terminals;

- disconnect the cable and check with a tester for current flow.

In case of a fault in the plug, it is necessary to restore the connection of the wires, it is possible to solder the terminals. If a violation occurs in the wires inside the cable, it should be replaced with a new one.

Checking contacts with a tester

If the lamp lights up, but the fan does not work, the following steps should be taken:

- make sure that the device is unplugged;

- disassemble the control panel, which is located on the fan casing;

- check with a tester all the key contacts for current conductivity;

- check speed controller with tester.

In case of failure of one of the buttons, you should either purchase a working replacement in the radio store or connect directly, bypassing. If the speed controller fails, it must be re-soldered, or also replaced with a new one.

The fan does not turn

The reason why the fan does not turn left and right is because of the malfunction of the crank.

To fix the breakdown, do the following:

- remove the back cover by unscrewing the fixing bolts;

- check the connection of the crank with the gear under the gearbox;

- put the crank in place, or replace if it is broken.

A situation may also arise when the turns are not completed to the end. In this case, it is necessary to check the progress of the gear selector switch along the vertical axis. In case of violations in its operation, it is necessary to disconnect the fixing bolt and grease the shaft, gear and upper part of the gearbox. If the plastic gear has worn out, and it was not possible to find the part on sale, then you will have to put up with the fact that the fan does not rotate.

Service gear

When installing the impeller after troubleshooting, you must follow the rules of balancing, otherwise the fan will not spin in normal mode. The simplest and most convenient way is static balancing.

Manually install the fan, set the initial rotation by hand and mark the top point of the impeller with a pencil or marker. Make a few more starts and check if the obtained advantage points coincide with the initial mark. If they do not match, then there is a malfunction in the bearings, which must be lubricated or replaced. If they match, take objects with different weights, such as nuts, pieces of electrodes, etc. For fasteners use electrical tape, adhesive tape, mastic, plasticine, thin wire.

Then they begin to attach them as a counterweight to the preponderance point in order to achieve the loss of its permanent place.For a more accurate selection, you can grind loads with a hacksaw. After finding the optimal weight, the load is welded or glued to the non-working side of the disk.

Screw balancing allows you to quickly determine the required settings empirically. But this option is not available on all fans.

You can also perform balancing on balancing goats by contacting specialists.

Possible damage to Timberk fans

Timberk fans have established themselves as inexpensive and easy-to-use devices for creating comfortable climatic conditions and maintaining air exchange in an apartment or office. Despite their good quality, they are prone to breakdowns.

Timberk Fan

During operation, customers noticed the following malfunctions:

- a drop in blowing force due to the soft plastic of the blades;

- there are times when a capacitor fails;

- the appearance of extraneous noise during operation;

- motor breakdown;

- rotor breaks;

- strong backlash appears;

- with prolonged use, the smell of burnt oil appears;

- legs bend and change geometry under the weight of the motor;

- overheating of the power supply;

- mechanical failures in places of fastenings.

In terms of price and quality, Timberk products are the leader in their segment. All devices have a manufacturer's warranty and can be replaced when contacting the service.

Malfunctions of fans in car cooling systems

The fan is switched on by a sensor located in the cooling system. In response to the signal, the cooler (cooler) turns on and directs an additional air flow to lower the temperature of the liquid and the motor. A number of failures are associated not with breakdowns of the fan itself, but with the operation of electronic sensors that are sensitive to changes in the system.

Often the fan relay clicks

Often clicks the fan relay in automotive cooling systems. The reason may be both the oxidation of the relay contacts and the temperature jumps causing it to trip. Diagnostics are:

- sensor;

- wiring;

- controller circuit for fan control.

Failure can cause engine damage, as improper operation of the sensors causes an incorrect setting of the ignition timing.

Cooling fan

First of all, you need to call in for diagnostics and ring the nodes with a scanner. If a damaged segment is detected, it must be replaced by installing a new one.

Frequent cooling fan on

Often the cooling fan turns on. It is considered normal when the idle periods of the fan exceed the duration of its operation. If this algorithm is violated, the reasons may be the following:

- clogged cooling system;

- lowering the coolant level in the radiator;

- malfunctioning thermostat;

- the pump does not work;

- the presence of air jams.

Clogged cooling system

It is necessary to rinse the thermostat and radiator, add coolant, check the operation of the water pump and replace it if necessary. Air plugs in the radiator are driven out by supplying a pressure of compressed gas. In the event of a sensor malfunction, if the temperature of its inclusion does not coincide with the rating parameters, the device must be replaced.

Air conditioner fan does not work

Reasons why not working air conditioner fanmay be the following:

- malfunctioning clutch on the main fan;

- the contacts of the relay switches have oxidized;

- blown fuses;

- the terminals of the supply mass are oxidized;

- insufficient refrigerant levels;

- armature brushes oxidized.

Air conditioner fan repair

It is better to call an electrician for service so that he and a multimeter examine the condition of the air conditioner and find out the cause of the breakdown.

Fan start temperature reduction

In the hot season, the factory settings of the fan enable relay do not allow to fully operate the car.In traffic jams, the engine may begin to boil, resulting in more serious damage.

Flashing ECU

In order to lower the fan on temperature, the following methods can be applied:

- reflash ECU settings when visiting the service;

- pour antifreeze with a higher boiling point, for example, 120 degrees;

- check the pressure level and tightness of the tank cap;

- put a trip computer with the ability to adjust the temperature for turning on the fan or the force button.

A lower temperature will allow the fan to start earlier, which will positively affect the operation of the engine.

Arbitrary fan on

The radiator fan must be turned on at a high engine temperature to cool it. However, sometimes the device turns on arbitrarily, despite the fact that the thermostat sensor shows a comfortable temperature of 25-35 degrees.

Clogged air filter

The reasons for this may include the following:

- low-quality fuel, additives in which reduce the flash point in the engine;

- insufficient level of antifreeze;

- clogged air filter;

- climate control is included;

- The cooler thermal switch failed.

If you suspect low-quality fuel, you need to measure the temperature of the exhaust gases. A heavily soiled radiator is flushed with plain water from a hose.

On a note! When the air conditioner is running, a constantly on fan is normal.

It is necessary to call in for diagnostics, check the operability of the thermostat. Top up or replace antifreeze if necessary.

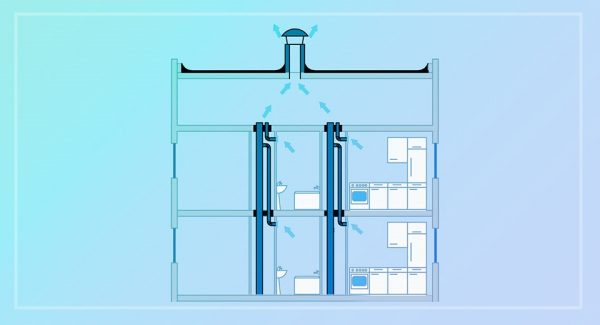

Ventilation problems in apartments

Built-in exhaust fans are much simpler in terms of design. But their cost is low and it is often easier to purchase a new one than to look for parts that have disappeared from circulation. Poor room ventilation may not be associated with the operation of the device itself, but with errors in the organization of the exhaust system.

Bathroom ventilation

When the ventilation in the bathroom is not working, the air becomes humid and not ventilated, the laundry does not dry well, mold may appear.

Normal ventilation

The reasons may be the following:

- the ventilation hole is clogged with dust and cobwebs;

- foreign objects in the mine;

- an exhaust fan is installed to draw in air instead of exhaust.

The correct solution to the problem is to contact the management company. Specialists lower the load into the ventilation shaft to the apartment itself to break through all the obstacles. In especially neglected cases, a camera is lowered into the mine to determine the location of obstacles. The ventilation shaft is opened from the entrance. You may have to go around the riser neighbors and check if they have improperly installed fans that interfere with the hood.

Advice! Suitable for a bathroom exhaust check valve fan, preventing the flow of air from the ventilation shaft.

Cooker hood

Exhaust ventilation is designed to remove unpleasant odors and stale air from the apartment. However, in case of violation of construction technology or due to other reasons, air begins to flow into the apartment from the exhaust outlet, despite the fan working.

Ventilation shaft pollution

Because of this, odors appear in the apartment. Cooking products are not removed from the kitchen.

The reasons may include the following:

- defects in the design of ventilation shafts and channels create reverse traction;

- strong gusts of wind in one direction blow air flows into the shaft;

- accumulation of steam and freezing air in ventilation;

- mine pollution by snow and waste.

As a result, the axial fan pulls the air masses from one shaft to another and the hood starts to work silently in the opposite direction.

To solve the shortcomings, it is better to invite specialists.They will evaluate the rationality of using the equipment in accordance with the documentation and conduct a quality examination of the installation and operation of the ventilation system. The received report will indicate all the shortcomings of the existing system and measures to correct them. Workers of the Criminal Code are obliged to clean the ventilation shafts from foreign objects. Also, to get rid of the effect of reverse draft in the hood, a deflector is installed to suck in smoke and create through the air flow in the kitchen.