Different types of air conditioning systems require a different approach to troubleshooting. There are four main types of air conditioning systems:

- The split system and self-propelled gun package are standard air conditioners.

- Mobile one-block conditioners – Ideal for cooling homes without air ducts.

- Portable systems for windows and wall blocks - designed to cool one room in a house.

- Evaporators, also known as humidifying air conditioning systems, are especially effective for removing heat with moisture in dry climates.

The article will consider the most popular of them.

The principle of the air conditioning system

Samsung air conditioners are equipped with an advanced self-diagnosis system. It is able to detect a malfunction and block the operation of the device until the problem is resolved. The reason for the termination of work will be available to the user in the information panel in the form of an error code.

Error interpretation on the Samsung AC030JXADCH model

Air conditioners of this series belong to the classic models of equipment for air conditioning. They use R-410A refrigerant. This equipment consists of two units. An air duct is not provided for this series.

Possible mistakes:

- E508 - there are problems with the installation of “Smart”;

- E202 - communication failure between the blocks when the signal from the indoor unit disappears;

- E201 - there is no communication between the blocks during tracking;

- E203 - a temporary problem when processing data from the compressor to the indoor unit;

- E221 - malfunction of the outdoor temperature sensor;

- E108 - repeated communication address;

- E251 - in the data received from the temperature sensor that the compressor pumps, there is an error, check the starting capacitor;

temperature sensor

- E231 - floor sensor COND is not working;

- E320 - problems with the OLP sensor;

- E404 - the system overload protection has tripped;

- E590 - EEPROM checksum is incorrect;

- E464 - system shutdown due to DC peak;

- E473 - Comp lock;

- E465 - compressor overload is possible;

- E468 - malfunction of the current sensor;

- E461 - failure of the inverter compressor;

- E469 - DC voltage sensor is not working properly;

- E475 - it is required to replace the fan 2 of the inverter;

- E660 - Failed to load the inverter code;

- E500 - receiving incorrect thermal data from the first inverter;

- E484 - overload PF C;

- E403 - lower compressor goes into frost protection mode, check for availability;

- E440 - floor temperature exceeded the default threshold and reached TheatJiigh parameter;

- E441 - floor temperature limit reached Tcooljow parameter;

- E556 - discrepancies in the capacity of indoor and outdoor units;

- E557 - requires adjustment of the remote DPM controller option;

- E198 - thermal breaker is not working properly;

- E121 - incorrect data of the indicator of room temperature;

- E122 - EVA indoor unit sensor is defective;

- E123 - EVA output sensor of the indoor unit gives an error;

- E154 - incorrect operation of room ventilation;

- El53 - Re-detect float switch failure.

Remedies for the Samsung APH450PG air

An approximate action plan for resolving errors on Samsung APH450PG air conditioners is floor models.The system of these devices uses R-22 refrigerant. There is a remote control, timer and air filter. It is possible to regulate the air flow. Design is a classic white case with colored frames.

- The code “E1” appeared on the display. The reason is a failure of the internal or external temperature sensor. Check this position - closed or open. Replacement may be required.

- Under the code "E5" hides a malfunction of the internal or external heat exchange sensor. Check serviceability. If operability is not restored, then replace.

- Code "E7" indicates a malfunction of the sensor responsible for heating. Check the wiring to the "heat generator". Especially the sensor mounting location.

The simplest malfunction that can be solved by the user without calling the wizard to restore the air conditioning software. You will need a control panel and a code. Samsung does not provide such information. A twelve-digit model code is entered manually. With a successful flashing, a melodic signal will sound.

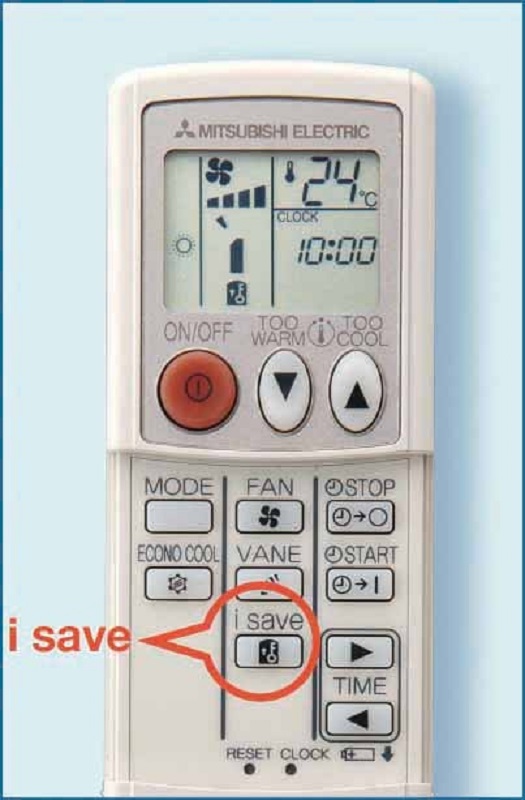

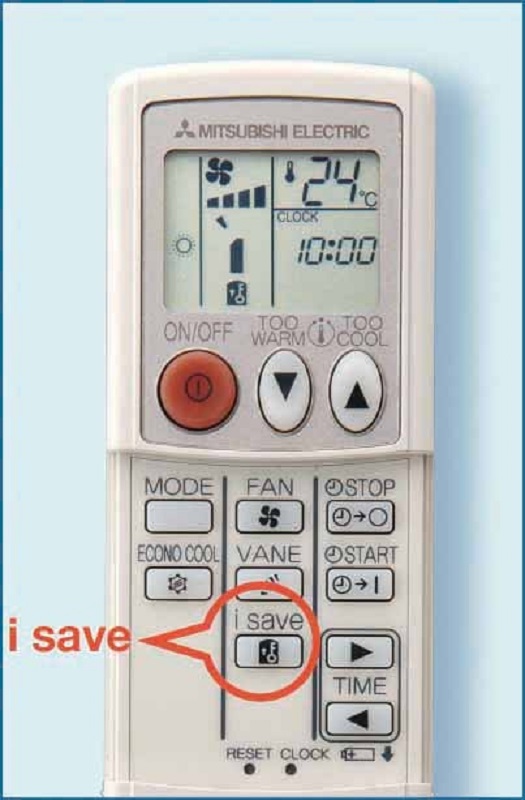

The control panel from which the code changes

Encoded Air Conditioner Faults Fujitsu

With color indicators and coded messages, Fujitsu warns users about problems. The most common Fujitsu DTCs that can be found in your air conditioning system are:

- Red light sensor (radar): blinks twice, like the green light sensor (DLS). Incorrect air sensor data. You should check if the device is in the “timer” mode, if the filters are clogged.

- Radar: 2 signals, FPP: 3. There is no sensor of the inner pipe. It is necessary to clean the pipes. Adjust the operation of the device in the ranges up to 10 degrees for ventilation and 30-60 degrees for heating.

- Radar: 3, Radar: 4 signals. The incoming air device is malfunctioning. The correct translational temperature should be between -3 and 4C.

- E0 - faulty indoor unit. The fault is the remote control. Check the wiring of the remote control, there could be damage that affects the communication between the unit and the remote control;

- E01 - violation of communication of the indoor and outdoor unit. Check wiring fastening.

- E02 - defective device that detects the opening. The device is missing or needs to be replaced.

Opening Sensor Installation Example

- E03 - The circuit breaker needs to be repaired or replaced.

- E05– pipe opening sensor. Correct the pipe sensor or replace it.

- E06– pipe opening sensor. The outdoor unit sensor is badly damaged, so it must be replaced to restore normal system operation.

- E07– Replace the defective pipe sensor.

- E08– the power source is to blame. The reason - a malfunction in the power supply - is a loose plug or damage to the wiring. Fix the problem and isolate the wiring.

- E09– defect of the float switch. The water level is too high. Drainage systems should be constantly checked for blockages. Reducing the volume of water will help.

- E0A– malfunction of the air sensor. The sensor is missing and a new one must be installed.

- E0C– malfunction of the external sensor dis. Replacing a missing sensor.

- E0dc– internal sensor fault. It is required to find the sensor with a malfunction and replace it.

- Е0С– high Disch temperature. Work pipe contamination or gas shortage. Get help from professionals.

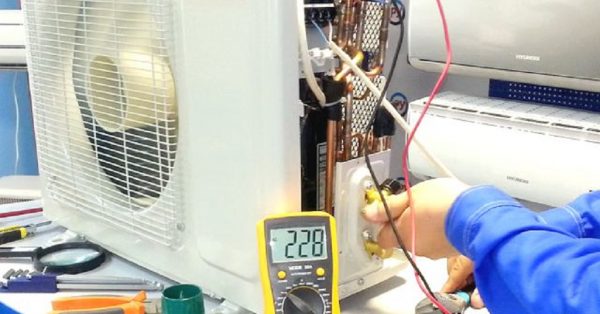

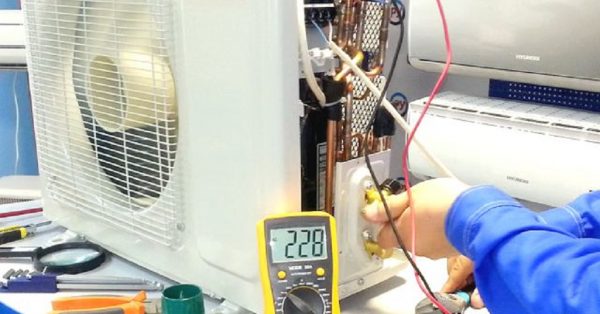

Any service is best entrusted to a specialist

- E11– Invalid model code. Check PCB compatibility.

- E12– internal fan failure. There may be a mistake with the fan and its motor. Inspect them and, if necessary, repair or replace.

- E13– incorrect O / D signal. The error is due to communications. Check for wiring.

- E14– refusal due to open PCB.The printed circuit board is damaged, in which case it should be repaired or replaced.

Gree’s diagnostic system has the same minimum functionality as Lessar, Pioneer and General Climate.

Industrial air conditioners and split systems

Error codes for industrial air conditioners:

- E1 - compressor pressure relief;

- E2 - coil malfunction;

- E3 - low air conditioning compressor pressure;

- F0 - the temperature meter inside the building is out of order;

- F1 - incorrect sensor resistance;

- F2 - the temperature protection of the external unit has worked;

- F3 - the temperature sensor circuit is open.

Split installation:

- E1 - a high degree of protection of the agent. Check pressure;

- E4 - compressor malfunction. Take a temperature reading;

- E5 - AC overload protection tripped. Check the power cable for a short, insulation integrity. Determine the electrical load entering the system;

- E6 - communication failure between the indoor and outdoor unit of an air conditioner split installation;

- E8 - temperature exceeded. The start LED of the system will give an eight-fold light signal;

- H6 - internal fan motor not responding. The system LED will give an eleven-fold light signal;

- C5 - Jumper breaks down. Fifteen-fold light. Correct or replace the “cap”;

- F1 - there is no contact or a circuit of the "environment" device has occurred. The temperature element must be replaced.

What you need to know about the repair and replacement of air conditioning systems?

Replacing any air conditioning unit can be one of the biggest costs a homeowner will need. Make sure that this is the right time to upgrade.

Necessary factors when deciding whether to repair or replace:

- Period of operation of the system or air conditioner – If the unit is purchased for more than ten years, the time has come to replace it.

- Frequency of necessary repairs - second or third repairs this year? Is the repair price approaching half the cost of the new system? Consent on such issues is the reason to stop throwing money away for inefficient service and to set aside funds to purchase a more modern system.

An example of a modern air conditioner

- Electricity bill - an increase in the numbers in the payment receipt from the electricity company may be one of the reasons for increasing the comfort bill in the cold season. Without an increase in the tariff, the numbers became more than a few years ago, which means that the system began to work less efficiently due to a longer operational period. The constant increase in electricity bills is a sign that the air conditioner has stepped over its heyday.

- Reducing the level of comfort - it is not difficult to correlate energy costs and a comfortable level in the room. Uneven temperature differences, cold air underestimates the limits set by the user, non-receipt of acceptable heat - all these are signs of the need to replace air conditioning systems.