- What is an indirect heating boiler and why is it needed?

- The principle of operation and the device of the indirect heating boiler

- Binding of indirect heating boiler with recirculation

- How an indirect heating boiler works in the summer

- Circuit diagram for indirect heating boiler with recirculation

- How to calculate the volume of an indirect heating boiler

- How to choose an indirect heating boiler. Indirect Heating Boiler Life

Different strapping for indirect heating boilers practically no different from a heating battery. Readers can do all this on their own. The main thing is to take into account the features in which circulation will be carried out in the coil. You can learn more about the connection methods and the operation of this type of equipment from this article.

What is an indirect heating boiler and why is it needed?

The scheme of operation of such heating equipment is quite simple. Boiler no different from the usual. The only thing that distinguishes them is the presence inside the heating element in the form of a spiral pipe. It is a coolant. Another name for it is a coil.

The life of this type of equipment is quite large. Like any other type of heater, an indirect heating boiler is necessary for heating and maintaining the desired water temperature for household needs. The average temperature in the working system is not more than 65-75 degrees Celsius. This will be enough to provide a family with hot water.

You can install such systems:

- at the cottages;

- country houses;

- showers;

- Offices

- apartments.

The only thing that needs to be calculated initially by the landlord is the pressure in the overall heating system. The boiler is used only for systematic heating of water. Use it as a heating system will not work. For convenience and maintaining a normal level of circulation, it is necessary to install an automatic pump that will maintain the pressure in the system at the desired level.

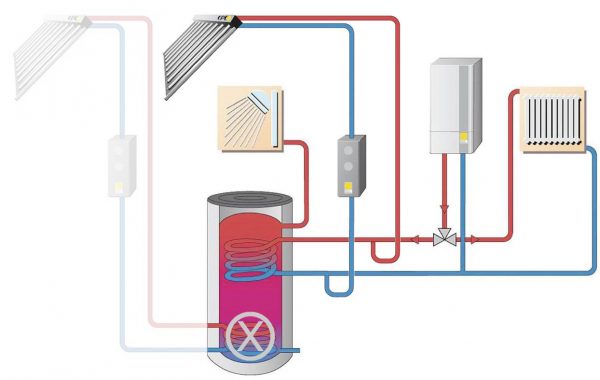

General view of the connected indirect heating boiler

It is important to calculate at the initial stages immediately whether the heating system will be able to maintain the temperature in the indirect heating tank at the required level without losing heat transfer around the entire perimeter. The boiler itself is selected by the displacement by the consumer. Such a tank is capable of holding up to 100 - 120 liters of water. It is important to properly equip it and place it inside the coil.

Water enters and is pumped out in the system through 2 specially installed outlets. One supplies water to the system for heating. The second serves to pump it out and supply it directly to the consumer in an already heated state. The pump, controlling the pressure level and temperature, will automatically circulate the coolant in the coil at the right time to maintain the desired temperature.

The principle of operation and the device of the indirect heating boiler

The principle of operation of the heating system of the indirect heating boiler and its device are quite simple. Hollow spiral tubes are installed in the tank, they are also snakes. Fluids circulate on an ongoing basis.

In order to have a constant circulation, pumps are installed that have automatic control systems for pressure and temperature readings. When the water temperature reaches the set values, the pumps stop working. Sources of coolants are working heating systems. Therefore, when the contents are heated in the tank compartment, there may be a slight decrease in temperature indicators on the heating element.It is worth noting that the heating of the liquid in the tanks is carried out in a short period of time. This allows you to almost not notice a decrease in degree in a short time period.

As soon as the liquid in the tanks reaches the desired temperature, this indicator will remain at the same level for a long time. Modern insulation material reduces the temperature loss in tanks. Expanded polystyrene or polyurethane types of foam do an excellent job of this task.

Scheme of operation of the indirect heating boiler

Each boiler has 2 nozzles. They are used for fluid intake and return. Fluid inlets are connected to the boiler heating systems. He sends to the coil, the coolant enters, which allows to increase the temperature in the tank with water. The return pipes supply and direct the heated fluid to the desired discharge location.

It is advisable to buy heating systems and indirect heating boilers from the same manufacturers. This will allow you to quickly and easily configure and connect the entire system. The principle of operation of indirect heating boilers connected to the boiler practically does not differ from a conventional water heater.

As for its device, there is also nothing complicated. In appearance, boilers are just like large tanks, mainly having the shape of cylinders. They consist of the following elements:

- housing;

- heaters to keep the temperature;

- galvanized steel tanks;

- thermometers for temperature control;

- heat exchanger and in the form of coils brought in;

- Magnesium anodes to protect the inside of the tank and elements from the formation of rust.

Heaters installed between the tanks and the bodies of the boilers themselves reduce the heat loss coefficients to 3 or 4 degrees in 24 hours. Thermometers placed inside allow you to control the set temperature of the liquid in the tanks.

Heat exchangers are spiral steel or brass tubes. They are located inside the boilers themselves. Practice shows that pipes are made of complex shape and are located closer to the bottom of the boilers. According to the manufacturers of such equipment, this allows to achieve a more uniform heating of the liquid in the tank. Magnesium anodes mounted in the upper part of the body protect the tanks from galvanic types of corrosion.

Binding of indirect heating boiler with recirculation

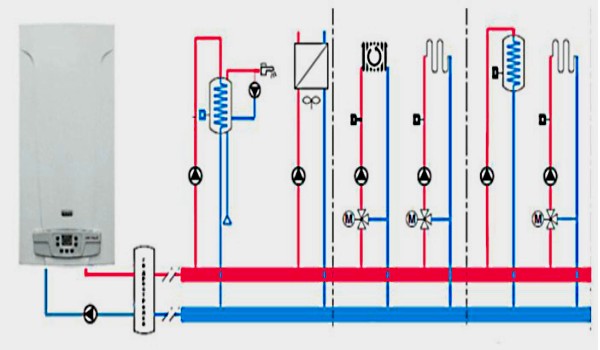

Tying for various types of indirect heating boilers with recirculation is carried out according to the drawing. When choosing components, it is important to consider the features of a home heating system.

For tying the water circuit to the boiler, the following 3 installation systems can be used:

- Installation of three-way valves.

- Installation of a double circulation pump.

- Regulation with hydraulic arrows.

The use of liquid recirculation systems significantly increases the performance of heating systems and by increasing the efficiency when heating liquids and rooms from boilers.

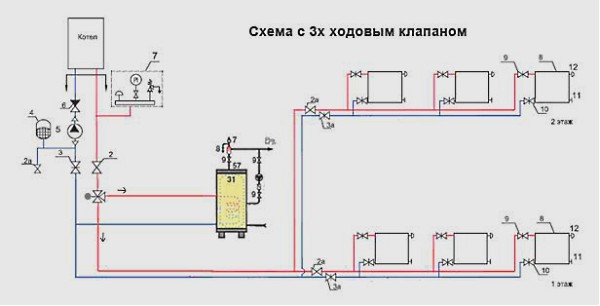

When installing indirect winding systems with three-way valves, it should be borne in mind that this method is intended for tanks with increased displacement. By developing such a system, it is calculated how the installation of a dual-circuit type of heating will be carried out.

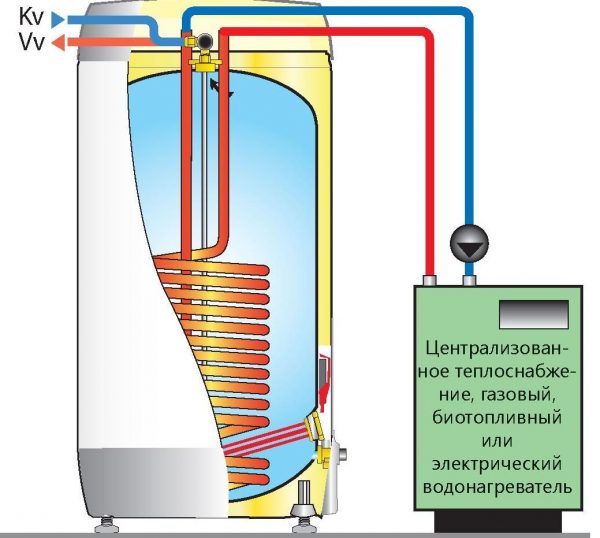

Connecting the boiler to boiler equipment

Monitoring water temperature information is very important. In a situation where the water in the boiler tanks has a set heating temperature much higher than in the heating circuits of the heating systems themselves, this can lead to incorrect functioning of all equipment.

This will cause the switch to heating circuits to fail. There are also options for installing indirect heating boilers using two circuits. The selection of the necessary option will also depend on the water in the water supply system.In a situation where the fluid in the main canal is of a high degree of rigidity, it is better to use the installation of systems with three-way valves, since double-circuit systems can quickly break due to clogging.

How an indirect heating boiler works in the summer

The heating tank is effective not only in the heating season. Such a design can maintain hot water not only in a separate unit, but also as the main source of hot water supply. For this, it is necessary that the coil is heated directly from the boiler equipment. It is especially convenient to use such a scheme in private homes and cottages where solid fuel and gas boilers are installed.

After the device is started, it will completely provide hot water along the perimeter of the system. Due to the presence of a coil and a thermostat inside the pump, the pump will constantly maintain the temperature in the system within 70 degrees Celsius.

Connected boiler to heating equipment and electric heating elements

This method is possible only if there is a separate boiler equipment that can operate from natural heating sources in the form of liquefied gas, coal or firewood all year round. If connected to central heating, this method will not be effective.

In order to maintain a normal temperature of the water, it will be necessary to install tena inside the boiler. They will heat the water inside the tank with electricity. Many immediately equip the tanks with a coil and electric heating elements for electric heating. During the period of heating shutdown, it is enough to connect such a device to a power outlet and the water will be heated again. Tena work on the thermostat. As soon as the water reaches the desired limit, the counters will work and heating will stop.

Circuit diagram for indirect heating boiler with recirculation

First you need to choose the right tank size. Having calculated the pressure in the heating system, since the water is heated by means of a coil, it is necessary to take into account the dimensions of the internal structure for piping.

During liquid recirculation in hot water supply systems, any point of the systems is provided with hot water without additional steps to spill it. To do this, contours are mounted along which fluid flows from the boilers for all systems. At the end, the water should again return to the boiler.

Recirculation is carried out using small pumps. They work with virtually no sounds. The established types of the system make it possible to maintain a stable fluid temperature at any point in the circuit around the house. There are 3 of the most common recycling schemes in a home:

- Installation of three-way or servomotor valves. It is used mainly for floor and wall type tanks. The design is noteworthy in that it has two outputs. One goes to hot water supply, which heats the heating equipment, the other to drain water for domestic needs.

3-way valve installation diagram

- Installation of 2 circulation pumps per 1 system. This type of circuit allows you to distribute the incoming water in the flow for heating and directly heating the liquid in the tank. Boilers of this type have built-in thermostats and automatic flow direction switches.

Installation of two circulation pumps in one system

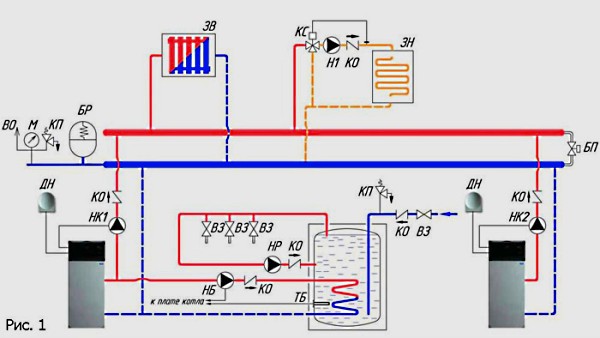

- Use of hydraulic arrows. They are needed when there are more than 2 circuits in the houses, which may include heating, underfloor heating, hot water, etc. It operates on the principle of heating from all sources of heat supply. There is 1 minus, which is that at the same time it will be impossible to get a source of warm water from several nodes.

Use of a hydraulic arrow

The selection of the boiler piping scheme and its connection to the heating system, taking into account the recirculation method, must be carried out in accordance with accurate calculations of the consumption volume in the hot water supply system.An error in the choice of connection method can lead to breakdown of the pumping equipment or complete inefficiency of the entire recirculation system.

How to calculate the volume of an indirect heating boiler

The description of the schemes presented above requires a correct calculation. A heating device is necessary to maintain the water temperature at the same level.

In order to carry out the calculation, it is necessary to consider an example of such an action. A family of 4 will be taken as a basis, where a large volume of warm water is consumed daily.

Washing dishes in 1 minute takes up to about 3 liters of hot water. If rinse is added here, then it will take about 8 minutes. Washing after two meals a day will require approximately 48 liters (3 * 8 * 2). It turns out that per week the consumption of water for washing dishes will leave 48 * 7 = 336 liters.

All family members take a bath 3 times a week. On average, about 80 liters of water are consumed per person. For a week, a family of 4 spends 4 * 3 = 12 * 80 = 960 liters on water procedures

On the remaining 4 days a week, each family member takes a shower. The average treatment time is 10 minutes. Water consumption per minute is 8 liters. One week a family member spends 4 * 10 * 8 = 320 liters. It turns out that a family spends 320 * 4 = 1280 liters per shower per week.

All family members in total spend up to 40 liters of water on small household activities per day. In a week this indicator will leave 280 liters.

As a result, a family of 4 spends water per week in the amount of approximately 336 + 960 + 1280 + 280 = 2856 liters. Taking into account errors and unforeseen expenses, it is better to round the figure to 2900 liters. The flow in the boiler is calculated by the hour. Therefore, it is necessary to recalculate everything in units. To do this, divide the resulting volume by the number of days and by 24 hours - the family spends 2900/7/24 = 17 liters per hour.

To calculate the ratio of temperature and power, we obtain the following indicator 17 * 0.0375 = 0.637 kW per hour.

How to choose an indirect heating boiler. Indirect Heating Boiler Life

The circulation boiler will do a good job of maintaining the temperature of the hot water in the network. In order to choose the right type of equipment, it is worth noting for yourself the following factors that will allow you to purchase exactly the type of tank that suits the design features of the heating system and the room:

- How much water is consumed by the residents of the room. The boiler will be effective if this indicator is from 1.5 liters per minute.

- Volume of the tank. For a family of 4 people, it is better to purchase equipment designed for at least 100 liters of water. At the same time, consumption savings with a temperature regime of up to 45 degrees will be at least 50% of the main flow of hot water.

- Productivity of boiler equipment. Before deciding to install an indirect heating boiler, it is advisable to determine if the gas or solid fuel boiler has enough power to heat both the room and the tank with water at the same time.

- Selection of the pump for the consumption of heated water. An important parameter that determines whether the selected pump can provide a normal rate of fluid circulation in the system.

- Tank interior materials. Different types of corrosion protection require care, be it glass ceramic or stainless steel. You also need to remember that magnesium anodes change every year.

- The calculated time for heating the water. A tank of 100 liters usually takes up to 2 hours. It is possible to accelerate this figure if you choose a boiler with a stainless steel interior. Then the heating will be carried out for a maximum of 20 minutes.

- Refinement of thermal insulation material. As mentioned above, polyurethane foam or mineral wool is best suited for this task.

- Dimensions of the boiler. Tanks of increased volume are quite massive. Therefore, it is better to allocate a separate room for these types of structures.

- Are there any security features in the package? Additional valves, thermostats and fuses ensure continuous operation of the boiler.

Typically, the service life of this type of heating equipment for the drainage network is up to 5-7 years. But there are models on the market that can last much longer - up to 10-12 years.

Internal and external structure of the boiler

The duration of the use of boilers is strongly affected by:

- activation frequency intensity;

- what quality is water;

- limiting temperatures of heating.

To extend the life of the boiler, do not set the thermostat to maximum temperature. If the boiler is at maximum, it will begin to function with the maximum possible load, and constantly turn on to maintain a high degree of fluid. It is enough to reduce the temperature to 60 degrees. This will extend the life of the boiler, and the enamel interior finish will not begin to crumble already in the next year after active use.