Probably, every car lover or person who has a favorite hobby is repairing something, dreams of a great welding machine. On the market you can find many different models of the welding device, but not everyone can afford it. But if there is a desire, then what to do? If at home there is a broken microwave, then do not immediately throw it away. It takes only time and effort to create a functioning welding machine from a broken part.

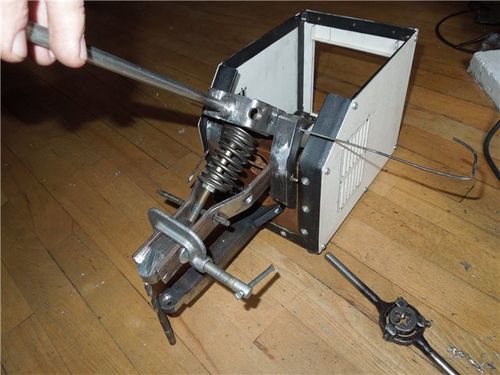

Spot welding machine

This article will discuss what constitutes a microwave transformer, and its application.

Transformer

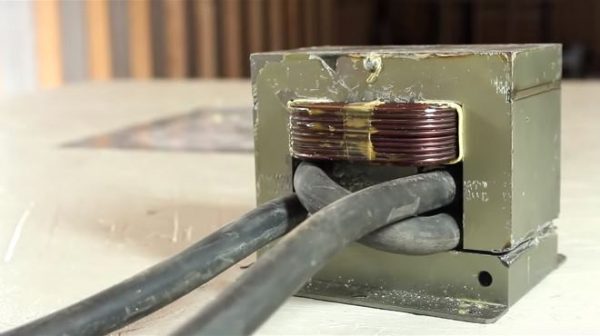

In the microwave oven there is a transformer, which is very useful for creating a device for welding. This important part consists of two ordinary coils of copper wire, which is wound around the core. There are primary and secondary windings. Coils with a winding have a different number of wire turns. This is necessary so that during connection to the primary winding there is voltage, and inside the second current appears due to induction, which has a lower voltage. The current strength should increase.

Transformer Removal

Extraction

For a home-made device for welding, a transformer is used, which has an average power of 750 watts. Using such a device, it is possible to connect metal sheets up to one millimeter thick. This electromagnetic device relates to boosting devices. To provide power to the magnetron, it is capable of generating a voltage that is 4000 V.

A powerful electronic device (magnetron), which has absolutely any microwave oven, requires high voltage for normal operation. Therefore, the transformer, which is connected to the magnetron, has fewer turns on the first winding. There are more turns on the secondary winding, a voltage of 2000 V is created here. But then the voltage doubles, thanks to the use of a specially designed doubler. Therefore, voltage measurements do not make any sense.

Remove the transformer from the microwave oven carefully and carefully. Do not use a hammer or any other heavy objects. First you need to unscrew the base of this kitchen appliance, after which you need to remove all the fasteners. After that, the transformer is carefully removed from the place where it is installed. From the "insides" of a microwave oven (microwave) you will need a magnetic circuit, the primary winding. The primary winding has a wire of large thickness and fewer turns.

The secondary winding is not needed, so it is dismantled. This procedure can be carried out with a hammer or chisel. You must act very carefully, otherwise you can cause damage to the primary winding. If during this procedure it is found that there are shunts in the transformer that are a limitation on the current strength, they should be disposed of.

If the magnetic circuit is not a glued structure, but a welded one, then the secondary winding must be removed using a carpentry tool (chisel).

Using a chisel

An ordinary hacksaw can be a replacement for a chisel.In the event that the winding is tightly packed into the window of the magnetic wire, then you should cut the wires, and then carry out its extraction by drilling it. During operation, care must be taken, otherwise the magnetic circuit can be deformed.

After the dismantling is completed, a new secondary winding must be wound. For this process, a wire that has a diameter of one centimeter is useful. If there is no wire with this diameter, then it must be purchased. Do not bother with the fact that the wire must be stranded, you can apply a bundle consisting of separate conductors. The main thing is to have a suitable diameter. At the end of mounting the secondary winding, the updated transformer will be able to generate current strength, which will be 1 kA.

If you need to make a welding device with more power, then using one electromagnetic device is unlikely to be enough. You have to use two devices.

Features of transformer upgrade

In order to create a secondary winding, it is required to perform the winding of two or three turns on the core. This will help to obtain an output voltage that will be 2 V. And will give 0.8 kA of short-term current strength. These indicators are enough for the full functioning of the spot welding device.

Winding a given number of turns can cause problems if the wire has a thick insulating layer. Eliminate it quite easily. It is necessary to remove the standard insulation, and then wrap the wire with electrical tape. The electrical tape should consist of cotton.

The position of the new secondary winding

The wire used for the secondary winding must have the smallest possible length. This will not allow its resistance to become larger, therefore, the current strength will not become less.

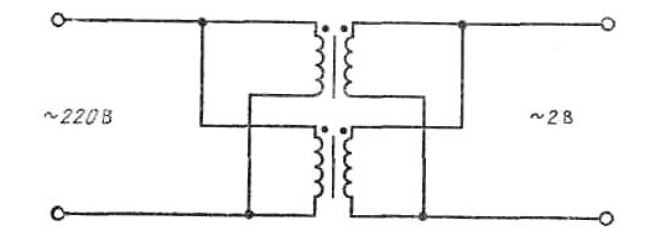

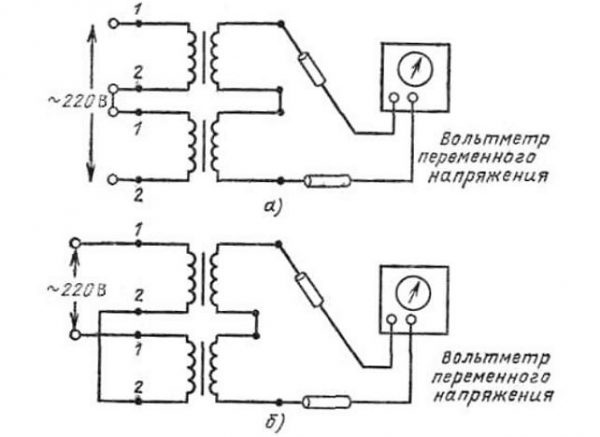

If you need to weld metal sheets that are up to five millimeters thick, then a device with much greater power is required for these purposes. To create such an aggregate, it is necessary to connect two electromagnetic devices in one circuit. To do this, you must strictly adhere to the rules. If the terminals of the primary and secondary windings are connected incorrectly, a short circuit problem will occur. In order to check whether the connection is made correctly, you need to use a voltage measuring device.

After the correct connection of the windings of two electromagnetic devices, you need to find out the current indicator. Most often, for transformers intended for spot welding machines, which are planned for use at home, current limits are applied. It does not exceed 2 kA. In the event that the indicator exceeds this value, there will be interruptions in the functioning of the electricity network. An ammeter should be used.

Tips for connecting two appliances

Suppose there are two identical transformers having the following parameters:

- Power value - 500 W;

- input voltage indicator - 220 V;

- indicator of output voltage - 2 V;

- current indicator - 250 A.

If you make the correct connection, you get a double indicator of the current strength, that is, 0.5 kA.

An increase in short-term current will also occur. But when creating a short-term current, you can see the loss. This is a consequence of the enormous resistance of the electrical circuit. It is necessary to connect both ends of the secondary winding with the electrodes of the unit, which is intended for spot welding.

First circuit

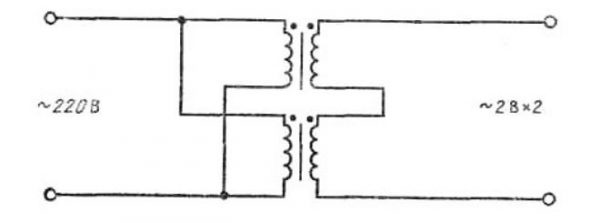

It happens that in the presence of two transformers with a large power output voltage is not quite enough to create an apparatus. In this situation, it is necessary to connect their secondary windings. They must have the same number of turns.

During their connection, it is necessary to ensure that the orientation of the turns is consistent.If this condition is not met, then protiphase will be created, and the value of the output voltage will be almost zero.

Second circuit

Definition of the same conclusions

It is possible that the terminals of the windings of electromagnetic devices that must be combined are not marked. Therefore, it is necessary to determine the same. Primary and secondary windings must be connected in series. After that, voltage is applied to the input, an alternating voltage measuring device must be connected to the output.

The meter can manifest itself from different angles, it depends on which direction of connection.

The measuring device can record the following:

- Show voltage.

- Do not register voltage in the circuit.

If the measuring device gives readings, this means that there are opposite leads in the circuit. This connection was not performed correctly, so the following phenomena can be observed here:

- The voltage value that is supplied to the input of the primary windings becomes less than half.

- On secondary indicators becomes more

Therefore, the meter will show the total voltage, which is equal to twice the input indicator.

Transformer Leads

If the measuring apparatus registers a zero value, this indicates that the voltages that come out of the secondary windings are equal, but have different signs. They are compensation for each other. One pair of windings is precisely connected by the terminals of the same name.

Therefore, with the right connection, it is necessary to focus on the voltmeter and its indicators.

Electrodes

Electrode Installation

When choosing electrodes, you need to pay attention to the diameter, which should correspond to the diameter of the wire, because the electrodes will be connected to this wire. You can use copper rods for this. If a low-power device is created, then soldering iron tips can be used.

During operation, the electrodes wear out a lot. Therefore, they must be sharpened regularly. Of course, over time they will need to be replaced.

So, the wire must be connected to the electrode, this is done using a copper tip. The tip is soldered.

The combination of the tip and electrode is carried out using a bolted connection. This connection must be reliable, because with an increase in resistance in the area of unreliable contact, the device will lose its power. To avoid this problem, it is necessary to make a hole in the electrode and tip. These holes should have the same diameter.

It is better to choose copper bolts, because they have minimal electrical resistance.

Body mounting

Housing

The case can be made of wood. The back of the panel must be equipped with a switch and a power cord. Holes must be made for these elements.

After this, grinding, priming and painting are carried out. Then - the assembly. Then you need 2 copper wires that need to be cut off. The length of the wires should be two and a half centimeters. Copper wires are electrodes. Next, the switch is mounted. Then the transformer is fixed to the tree. This fastening is carried out using ordinary screws. For safety and convenience, it is necessary to mount a mikrik. This button is attached to the upper arm. Remember to isolate the joints.

To create a unit for spot welding, incorporating a transformer from an old microwave oven, is quite easy. The main thing is to follow certain rules and nuances, and everything will work out.