What role does the pressure switch play in the washing machine? The main objective of this part is the measurement of the volume of the liquid, as well as the determination of overcrowding or deficiency. This device is an indispensable spare part for washing machines, because without it it will not be possible to determine how much water needs to be pumped into the tank, and most importantly, if something else needs to be added to ensure stable operation of the equipment. For convenient control of all washing processes, this part is also used. But in some situations, problems may arise and then the setting of the pressure switch will be necessary.

Small detail - important features

What is the pressure switch needed for and what is its role

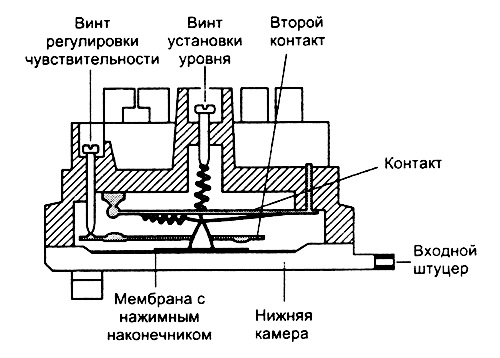

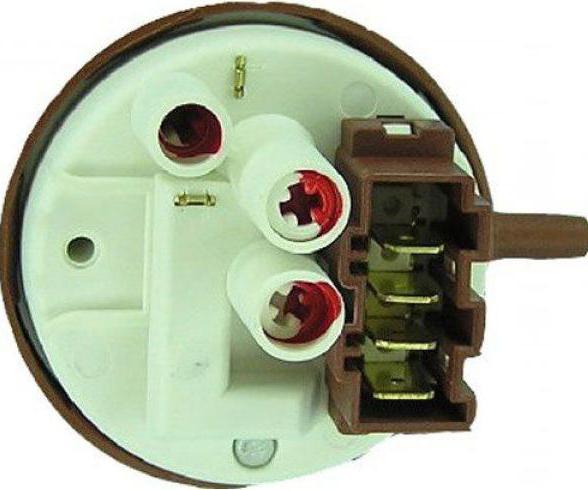

What is a pressure switch and why is it installed in a washing machine is already clear, but what kind of appearance does it have? This device has a small rounded shape made of plastic. A pair of wires and a special tube are connected directly to it. For the functioning of the sensor, showing the volume of the filled water, it will be connected to the tank, where a very high pressure indicator is noted.

As soon as the pump starts to pump water, then with the help of the tube the pressure will gradually begin to increase. It will fully correspond to the amount of fluid collected. As soon as there is enough water in the tank, to stop its supply, the installed relay closes first and after that a certain contact is opened. Thus, the main processor of the washing machine, which controls its operation, receives the necessary signal that enough water has accumulated in the tank to start the water cycle and the washing can be started.

Appearance of the part

How to adjust the pressure switch?

In order for the pressure switch to accurately control the amount of fluid collected, it is necessary to set some settings and set the optimal pressure level. Due to this, he will be able at the right time to give a signal to stop the water supply and start the selected washing mode. As a rule, the manufacturer sets the sensor for the washing machine directly, setting some basic standards for its model. The owner very rarely encounters a similar problem that needs to be addressed as soon as possible. If this still happened, first of all you will need to find out how to check the pressure switch installed directly in your washing machine.

Arrangement of the sensor and screw for adjustment

Sometimes you can find owners of washing machines that knock down the established standard settings that affect the operation of the pressostat. Any factors can cause problems. It is enough to at least slightly change the position in which there is a special screw connected to the machine body. If you turn it in one direction or another, this will contribute to an increase or decrease in the pressure level and to a malfunction of the water level control, which will lead to incorrect readings on the sensor.

Do not try to change the settings yourself.

What malfunctions may occur in the work of the part

When there are any malfunctions in the work, then checking the pressure switch of the washing machine is a prerequisite.It will allow you to determine what exactly broke or provoked the malfunction of this part.

Instrument Location

The fact that there were certain problems with the sensor can suggest the following:

- The washing process starts at a critically low level of liquid, or no water at all. Most often, certain programs are activated in the machines, which are activated when the mode is selected. In the event of a malfunction, the automatic machine can start the temperature sensor of the washing machine and the heating element when the desired degree has not yet been reached for washing. In the end result, this can cause the heater to burn out, which should not perform such a function.

- A lot of water enters the drum or its amount may be a little insufficient. In some situations, water can accumulate without stopping, which can cause serious damage to the equipment itself.

- At the end of the next cycle, dirty water is not removed from the tank. Sometimes, at the end of the spin program, the loading hatch may become blocked. It is worth noting that spin problems are not always caused by a breakdown or a malfunction in the pressure switch.

- The washing machine does not rinse the washed laundry.

Such a small small detail is responsible for tasks that are so important in the washing process. Therefore, you need to inspect it from time to time and at the same time it will not be superfluous to check the temperature sensor built into the washing machine.

How to check the pressure switch for problems?

Sometimes an unpleasant situation occurs when the pressure switch starts to “fail”. In this case, the whole system will function incorrectly - the machine will cease to execute the given commands, failures will begin.

The cause of the malfunctioning of the washing machine can only be determined during its analysis and examination of all important details, including the sensor and the pressure switch. Parsing a machine takes time, so the first step is to find out exactly where the pressure switch is located in your model of washing machine.

A small part can cause serious problems.

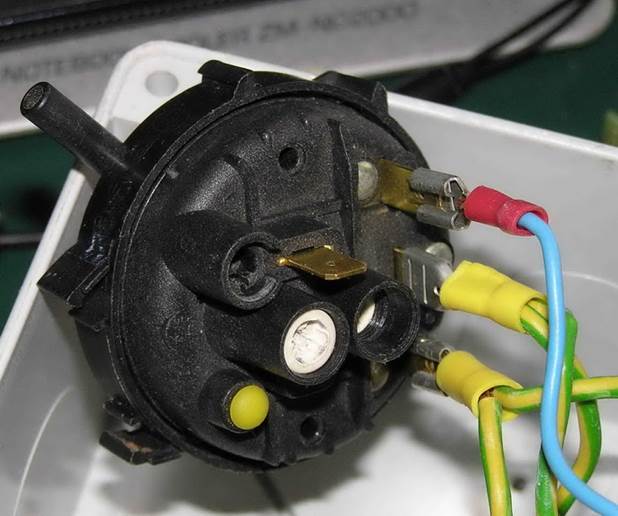

- First of all, you need to carefully remove the top panel of the washer. To do this, just unscrew the bolts and slightly move the panel in the direction that will be opposite from you. In most modern washing machines, the pressure switch is located in the upper part near the side wall.

- Experienced mechanics say that it will be sufficient to carefully disconnect the water level sensor. It is fixed in most cases with a couple of screws that can be unscrewed in just a few minutes.

- then you need to carefully disconnect the connected contacts and tube from the pressostat. It should be noted that the hose is fixed by using special clamps. There are two options in this situation. Or disassemble them, which will be long enough and problematic. Or you can just cut them and install new ones.

After the pressure switch has been removed, inspect it from all sides, paying attention to all, even minor damage. There should be absolutely no damage or even minor formations on the case. It is also worth checking the tube and the state in which the material for insulation of the wiring is. If necessary, you need to clean all possible blockages and remove damage. We advise you to pay attention to the contacts of the water level sensor. They must be thoroughly cleaned.

Contact Location

Now you can check the pressure switch itself. To do this, you need to use a hose, the length of which will be approximately ten centimeters. The diameter of the hose must be exactly the same as that previously removed. Connect the tube to the inlet fitting of the water level sensor and blow it with all the force. The sensor should create clicks at this moment. Their number will be different, depending on how hard you blew into the hose.

If during this procedure the pressure switch does not make absolutely no sounds, then this can only mean one thing. It does not work and the part must be replaced.

In order to surely understand that the water level sensor is not suitable for further use, you must use a multimeter. With this device, resistance indicators are measured. If during the injection into the air hose the resistance level does not increase at all, then it is worth purchasing and installing a new pressure switch.

Timely check of the sensor is the key to the normal operation of the washer

This device, even taking into account the size, plays a very important role in the operation of the entire washing machine. If the sensor ceases to function, then you will not be able to start even the simplest washing mode. In some cases, this kind of failure can cause more serious problems with the equipment.

Replacing a water level sensor is troublesome, but the process itself is not very complicated. It is worthwhile to carefully monitor the condition of the washing machine and then such a breakdown will be fixed in time, while none of the important spare parts will suffer.

Replacing a water level sensor in an automatic machine

If after checking you find that the pressure switch is not working, then it should be replaced immediately. This item is inexpensive, so everyone can buy it. You can buy spare parts for repair via the Internet or in a specialized store. To choose the right device, tell the seller which brand and model needs to be replaced with the sensor. He will select the suitable part for you. You can also purchase a pressure switch, given its number. As a rule, such a number is indicated directly on the part.

Replacement must be timely.

Replacement does not require technical skills. All you need to do is put a hose on the sensor, attach the necessary contacts back and tighten with bolts to the place where the broken part used to be. Next, start the washing machine to check its normal operation.

The replacement process is very simple.

If the process of checking and replacing the sensor seems too complicated for you and even the circuit does not help you, then you should consult a specialist. They will quickly check the pressure switch and replace it.

In order not to disrupt the operation of the water level sensor in the drum and in the whole system, carefully monitor the operation of the washing machine and take care of the washing device itself.