- Which steam generator is suitable for different baths

- How the steam generator works

- Water supply methods

- Independent manufacture and installation of an electric steam generator

- Preparation of equipment and materials

- Step-by-step steps when using a gas bottle

- Step by step using a pressure cooker

- Recommendations for use

- DIY steam gun

- Step by Step Actions

A regular visit to the steam room will help to improve the body and get a lot of pleasure. To get steam, the majority of bathhouse enthusiasts splash water on hot stones from time to time, but you can make a steam generator with your own hands that will produce the optimal amount of steam without spending too much water. Such a device has small dimensions, differs in simplicity of design and allows using it without the presence of a furnace, even in urban apartments.

The factory devices have software control that allows you to set the modes of the Russian bath, Finnish sauna or Turkish hammam. For this, the temperature and volume of the supplied steam are regulated. The steam generator for the bath, made by yourself, can also be adapted for all three modes. The resulting steam will be more delicate than with hard pouring water on hot stones.

Which steam generator is suitable for different baths

Discarding the differences in traditional methods of construction and the choice of materials for each type of bath, we can distinguish the main features of the Russian, Finnish steam room and hammam, which consist in the current regime of temperature and humidity:

- In a Russian bath you need to provide an average temperature of 60 and about the same humidity in percent.

- the highest humidity (up to 90%), but low temperature (40-45) is needed.

- In a Finnish sauna, dry hot (100) air with a humidity of about 10-15%.

The dryness of the hot air in the sauna is ensured by the open door of the oven, so that hot stones can more effectively remove moisture. It is not necessary to install a steam generator here, a small-sized steam gun is suitable.

In a hammam, where a large amount of low-temperature steam is required, you can create this mode by pouring a lot of water on hot stones, but you need a large volume of the furnace. A steam generator is indispensable here, which guarantees the production of light dispersed steam, and not heavy and damp.

The Russian steam room is a combination of a sauna and a hamam, absorbing their best sides. The desired performance can be achieved using a sufficiently productive steam generator that produces steam at elevated temperatures.

An additional advantage of using a steam generator is the accelerated heating of the room (this is especially true in cold weather) and prolonged heat storage.

How the steam generator works

The principle of the steam generator is reminiscent of boiling water in a kettle when steam is released through a narrow spout. Using the valve on top of the hermetically sealed tank, the pressure level inside is regulated. The temperature of the steam depends on the pressure. Thus, different types of baths are created.

In order to use the steam generator together with the stove, a design is needed so that the steam from the apparatus enters the stones for the purpose of additional heating. As a result, the steam generator consumes less electricity, and due to a slight decrease in the heating of stones, the furnace’s life is extended. Such a bath arrangement is preferred, but if it is not possible to fold the furnace, the steam generator can be used independently, consuming more power.But you can save on expensive construction of the stove.

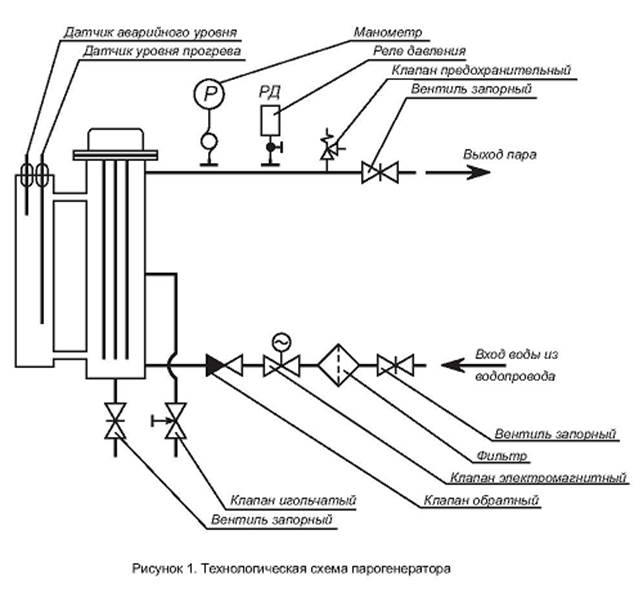

The main structural units of the steam generator are:

- water tank;

- heating elements;

- evaporation chamber;

- safety sensors and valves;

- Control block.

On the outside of the metal case are:

- a pipe for connecting to a water supply system;

- drain valve;

- several connectors for connecting sensors;

- steam outlet;

- control device.

Important: To equip a modest steam room up to 5 cubic meters. m the power of the steam generator should be 4-5 kW. For large rooms up to 18 cubic meters m need at least 12 kW.

Depending on the type of heating elements, steam generators are:

- Stoves. Special narrow chambers are made on the side walls of the furnace, into which water is poured. It is heated by the fire of the furnace and evaporates after boiling.

- Electrode Liquid heating is based on the principle of current flow between the electrodes.

- With the use of tubular heating elements - heating elements.

- Induction. A hollow metal loop is constructed that heats up from self-induction currents. Fluid circulates inside the circuit.

Water supply methods

Water is supplied to the steam generator tank by two methods:

- independent filling of water by the user;

- automatic feed from the water supply.

If the steam generator for the bath is made by hand, automatic water supply is more difficult. Another drawback of this scheme is the content of impurities in tap water or its increased stiffness quickly provoke the formation of scale, which will require frequent cleaning. With manual filling of the tank, distilled water can be used.

You can also see for what reason water can flow from the steam generator.

Independent manufacture and installation of an electric steam generator

Factory devices for steam production are convenient and functional, but are not cheap. The price of a small home appliance ranges from 20 thousand to 80 thousand rubles. Therefore, many craftsmen are thinking about how to make a steam generator yourself.

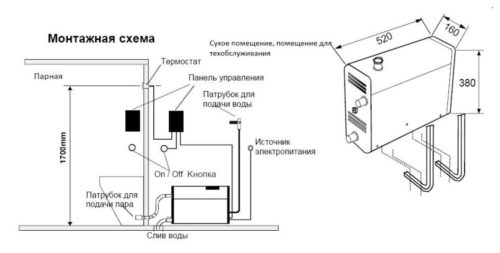

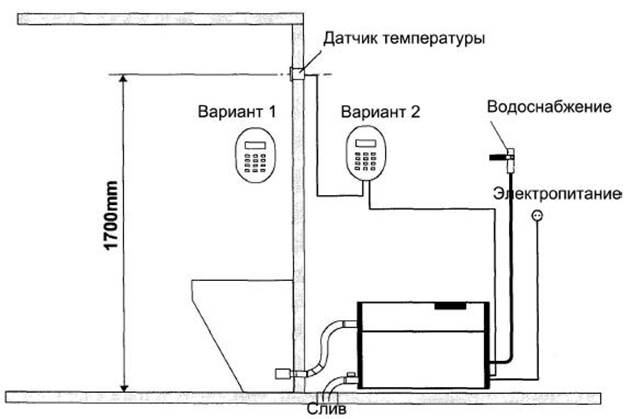

Features of installing a steam generator

- The device is installed next to the steam room.

- The steam line is mounted so that its length is as small as possible. Otherwise, condensation will form. During installation, bends in the steam line should be avoided to prevent accumulation of fluid in pockets.

- Power supply is provided from a network of 220-380 V.

- In the steam room, it is necessary to equip effective ventilation.

In order to adhere to a clear plan on how to make a steam generator for a home bath with your own hands, you must be guided by the drawings of the installation diagram of a home-made apparatus.

Preparation of equipment and materials

What will be needed for the manufacture and installation:

- ball valves that withstand elevated temperatures;

- heating elements (heating elements);

- gaskets for heating elements (they must be heat-resistant);

- safety valve;

- a hose is used for the steam line;

- drives with corresponding connecting diameters;

- a tank that can withstand high pressure (for example, an old gas cylinder);

- pressure gauge.

Important: The volume of the tank is selected based on the size of the steam room. General rule: for a 10-liter capacity, the power of the heating elements should correspond to 3 kW.

A gas cylinder is prepared before use:

- Checks the integrity of the walls, the absence of defects.

- The top valve is carefully removed.

- Water is poured into the cylinder to completely displace gas residues.

- The upper part of the cylinder is cut off at the weld.

- The inner surface of the container is thoroughly washed with detergents.

Step-by-step steps when using a gas bottle

- From the bottom of the selected container, a heating element cuts at a distance of about 10-15 mm from the bottom.When installing several heating elements, it is better to first embed and fasten one, and then drill the following holes to exclude them too close. If the sleeve has to be welded to install the heater, the assembly design must withstand high pressure. The heating elements are sealed using heat-resistant gaskets on both sides of the hole. It is necessary to provide for the possibility of free removal of the heater in case of failure.

- Runaways are welded to the cut-off cover for connecting control devices (contact pressure gauge with arrows, safety valve). You can combine them together (security group), then only one hole is used.

- Having departed 10 cm from the bottom of the cylinder, a nozzle for supplying water crashes. The water tank from which it will be supplied to the steam generator is constructed of translucent plastic and connected to the apparatus with a hose of heat-resistant material. Thus, the amount of incoming water is easily controlled.

- Another method can be used to determine the water level inside, but it will require more holes. A pipe for the crane is welded to the side. It must be placed below the required upper level by 1-1.5 cm. When filling with water, the tap opens and water flowing out of it is a signal to end the filling. It must be ensured that the valve is turned on before turning on the steam generator.

- The steam outlet valve will be a regular cylinder valve. It connects to the steam line. In order to prevent steam from escaping in a narrow stream, a 50 cm steel pipe with numerous holes made on it can be installed to disperse it.

- A lock is installed on the upper cut of the container, which ensures tightness with a rubber seal.

- The lid and the lower part are connected by means of L-shaped studs and nuts.

It is possible to make a sealed connection of two parts much easier - to weld them, but then the device will be unrepairable.

The designed device must be tested in action to identify and eliminate deficiencies.

Important: As a manometer, it is recommended to use a model with a relay that connects to a magnetic starter. The relay is set to trip upon reaching the set pressure value. This increases the security of the device.

Step by step using a pressure cooker

From a pressure cooker it’s convenient to make a steam generator with your own hands for a small steam room. It will require much less manipulation than in the case of a gas cylinder.

- Holes are drilled to insert the heater at a height of 10 mm from the bottom of the pan.

- The heating element is fixed with studs, bolts and nuts.

- Heat-resistant insulating gaskets are required at the attachment point. You can also make them yourself. A sheet of thick paper is laid on a clean horizontal surface and a layer of sealant is applied to it to occupy a significant area of the sheet. Then the layer is leveled, covered with another paper sheet and glass. To increase the pressure, something heavy is placed on top. After drying out the silicone layer, appropriate gaskets are cut out with a tube of suitable diameter.

- After fixing the heating element, water is poured into the pan to check for leaks.

- A little below the heater is a copper curved tube for supplying water.

- Since the capacity of a home-made steam generator is very small, there is a danger of rapid boiling of water, which will damage the heating elements. It is necessary to ensure the flow of fluid in automatic mode. One solution is to place a separate container next to the home-made steam generator connected to the water supply pipe. Both devices must be at the same height. A float valve mounted at the bottom of an additional vessel opens when the liquid level drops and adds water to the steam generator.

- A hole is drilled in the pan lid and a steam outlet hose is attached using connecting fittings.

Recommendations for use

- It is preferable to install the steam generator in a room adjacent to the steam room, as it is an electrical appliance that is dangerous in high humidity conditions.

- The steam pipe must be inclined so that the condensate can drain without forming a plug.

- Normal tap water should be pre-cleaned with a filter. Acetic acid can be added to the liquid to remove scale.

- When performing various wellness procedures, herbal infusions or essential oils are added directly to the water.

Important: In order to ensure electrical safety, grounding is performed on the metal housing of the steam generator. To connect, use an RCD.

DIY steam gun

In addition to electrical steam generators for a Russian bath and sauna a steam gun is used. This simple device does not require drawings and complex calculations. Since the gun is installed in the finished stove-heater, it is designed depending on its size and shape.

The principle of the steam gun is to get water from the pipe into which it is poured from above onto the lower stones of the furnace. Passing through them, the liquid turns into steam and enters the room.

For what purposes the gun is designed:

- deliver water to the lower region of the heater;

- produce additional steam heating, making it drier and lighter;

- leave steam for some time at the top of the heater, warming it and reducing humidity.

All structural elements are assembled from parts that are present freely in stores. They must be corrosion resistant. If it is not possible to buy stainless steel parts, they are suitable from cast iron - they will also last a long time.

First you need to prepare the materials:

- steel funnel (preferably stainless steel);

- corrugated pipes (approximately 2.2-2.5 m);

- tees, transition angles and pipe connectors;

- fittings for connecting corrugated water pipes.

You can buy a check valve ready-made or use a plumbing valve. It is necessary to prevent the reverse splash of water and is used as a dispenser for its supply.

Thread connections are sealed with fum tape, for example.

Step by Step Actions

- A funnel is prepared (taken ready or made of stainless steel sheet)

- A non-return valve is mounted and a corrugated pipe is connected using a fitting. It can be ordinary tap.

- Using the connecting elements, a device of that shape is made that is suitable for laying in a stove-heater.

- Pieces of corrugated pipe will serve as steam diffusers. They drill a series of holes up to 2 mm in diameter. If during testing water evaporates at an accelerated rate, some holes can be closed with self-tapping screws.

- The finished steam gun is placed in the oven and laid with stones from above.

In the first tests, a homemade device is filled with liquid in a limited amount, and the furnace does not heat up to the end. If the tests are successful, then you can test in the operating mode.

Homemade generator is easy to manufacture, and the craftsman will make it in one day. It is impossible to replace the factory appliance completely, but as a result, a more comfortable atmosphere and better conditions for recovery will be created in the bathhouse.